Zeta has over 26 years’ experience with safety critical designs

Safety is critical in automotive design. It’s necessary to protect the investment of the vehicle’s owner. Most important, people’s lives are at stake. That’s why modern automobile manufacturers incorporate various safety features, including airbags, stability control and tire pressure monitoring. But safety in design goes beyond those obvious protective systems. Safety is a central design consideration for any piece of electronics within the automobile – no matter how large or small.

Whether under the hood or in the cabin, today’s advanced chipsets are highly susceptible to numerous electrical hazards common to the inherently harsh automotive environment. Typical automotive electrical hazards or transients include lightning, electrostatic discharge (ESD) and switching loads in power electronics circuits.

Microprocessor design for automotive environments including conformance to EMC and ISO standards (ISO-16750-2).

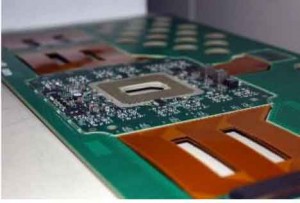

- PCB layout – Zeta uses expert design for manufacture taking into account high current carrying conductors and component placement, including enclosure and connector design.

- Firmware & Software Algorithms Development – Zeta has many years’ experience in embedded algorithm development for efficient and optimal product development.

- FMEA – Failure Mode and Effect analysis is conducted in all design reviews to ensure a compliant and fully assessed product.

- LABview – Zeta uses labview to provide for a diagnostic and debugging platform which is user friendly and offers highly advanced functionality along with data logging.

- Volume production – Zeta has a full procurement team in order to ensure that development flows via project management into production with a ramp up for volume.

- VCA Type Approval – Zeta has experience in ensuring final products are validated to the latest harmonised test procedures especially for EMC testing.